Tool grinding machine manufacturer

Loading the vertical pallet storage unit

Loading the vertical pallet storage unit

Picking up the workpieces

Picking up the workpieces

Depositing in transfer station

Depositing in transfer station

Picking up with gripper

Picking up with gripper

Gripper check

Gripper check

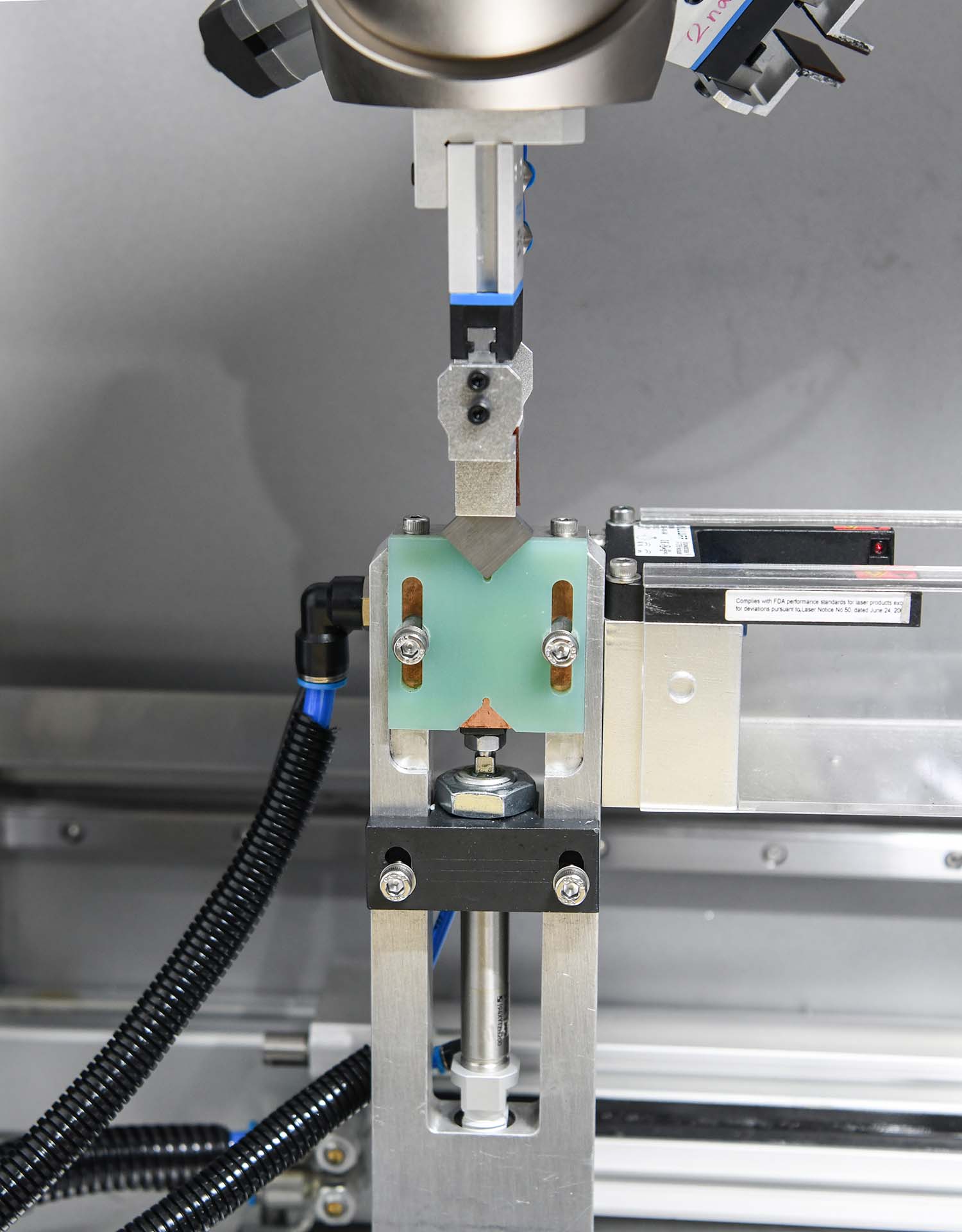

K-land grinding left side

K-land grinding left side

Gringing area

Gringing area

K-land grinding right side

K-land grinding right side

Permanent conditioning system

Permanent conditioning system

Control panel with Bosch Rexroth control unit

Control panel with Bosch Rexroth control unit

Manufacturer

As a tool grinding machine manufacturer, HDC Huttelmaier is especially proud of the CPG400 special grinding machine for carbide. The CPG400 automatic indexable insert grinding machine is a CNC grinding machine specially designed for machining ultra-hard materials (e.g. PCBN, PCD, ceramics, cermets) on inserts and wear parts in the geometry area of inserts.

Showroom

We invite you to our showroom for precision grinding machines in Schorndorf near Stuttgart to test your workpieces yourself on the CPG400.

Retrofit

HDC Huttelmaier was founded in 1947 and offers machine overhauls and machine modernization for over 140 machine tool manufacturers in the field of high-precision turning, milling and grinding machines.

A special feature here is certainly our retrofit for high-precision insert surface grinding machines. Take advantage of our many years of experience, especially with high-precision Wendt surface grinding machines.